PCKW series slime crusher

Key words:

Classification:

Coal Crushing Technology And Equipment

- Detail

-

- Commodity name: PCKW series slime crusher

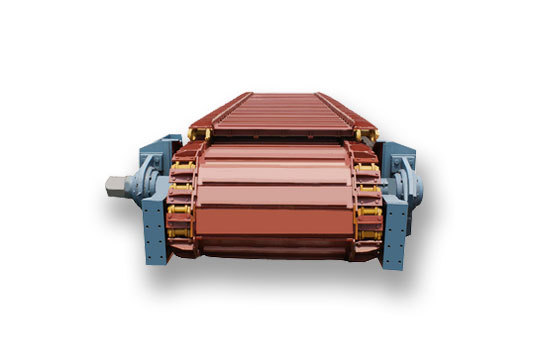

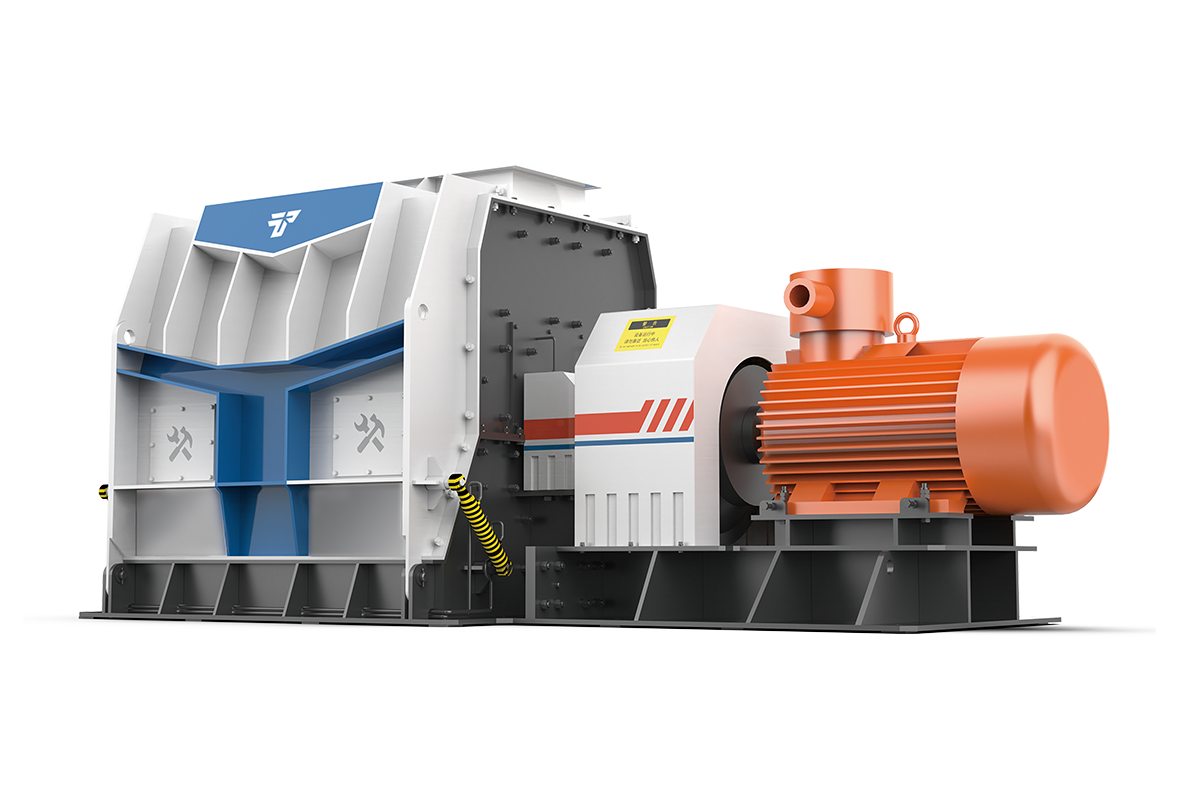

PCKW series slime crusher is mainly composed of motor, hydraulic coupler, rotor, casing, frame, screen, hydraulic opening device and other parts. The motor drives the rotor to rotate at high speed through the transmission system to beat the coal slime filter cake. The screen is located below the rotor. The coal slime filter cake interacts with the screen through the hammer head. The fine coal slime particles pass through the screen holes, and the large coal slime filter cake continues to be beaten and crushed on the screen. It is mainly used for crushing the coal slime after the ultra-high filter press in the coal washing industry.

PCKW series slime crusher is mainly composed of motor, hydraulic coupler, rotor, casing, frame, screen, hydraulic opening device and other parts. The motor drives the rotor to rotate at high speed through the transmission system to beat the coal slime filter cake. The screen is located below the rotor. The coal slime filter cake interacts with the screen through the hammer head. The fine coal slime particles pass through the screen holes, and the large coal slime filter cake continues to be beaten and crushed on the screen. It is mainly used for crushing the coal slime after the ultra-high filter press in the coal washing industry.

A hydraulic coupler is arranged between the motor and the rotor, which has soft start effect, overload protection function and impact relief function: the hammer head is made of wear-resistant alloy material and has long service life; The screen is made of wear-resistant plate, and the screen hole adopts a gradual structure from small to large. The particles are uniform and the material is not easy to block. The equipment is equipped with hydraulic opening devices, which can be opened from the side plates on both sides of the casing to facilitate cleaning and maintenance of the crusher; it is equipped with material blocking alarm and electrical control safety protection device to avoid equipment damage caused by abnormal operation.

The maximum feed size is 500mm and the maximum production capacity is 350 t/h.

Product inquiry

Note: Please leave your E-mail and our professionals will contact you as soon as possible!