CRUSHING OF MATERIALS WITH HIGH VISCOSITY AND LOW HARDNESS (solid construction waste, oil shale, coke, petroleum coke, clay, electrolytes, bauxite, etc.)

Key words:

Classification:

Non -Coal Crushing Technology And Equipment

- Detail

-

- Commodity name: CRUSHING OF MATERIALS WITH HIGH VISCOSITY AND LOW HARDNESS (solid construction waste, oil shale, coke, petroleum coke, clay, electrolytes, bauxite, etc.)

Construction waste mainly refers to the waste generated in the process of new construction, reconstruction, expansion, maintenance, decoration and demolition of various buildings, structures, pipe networks, etc. It mainly includes construction residue, waste brick, waste tile, waste concrete, scattered mortar and concrete, in addition to a small amount of steel, wood, glass, plastic, various packaging materials and so on.

CRUSHING OF MATERIALS WITH HIGH VISCOSITY AND LOW HARDNESS (solid construction waste, oil shale, coke, petroleum coke, clay, electrolytes, bauxite, etc.)

SOLID CONSTRUCTION WASTE

Construction waste mainly refers to the waste generated in the process of new construction, reconstruction, expansion, maintenance, decoration and demolition of various buildings, structures, pipe networks, etc. It mainly includes construction residue, waste brick, waste tile, waste concrete, scattered mortar and concrete, in addition to a small amount of steel, wood, glass, plastic, various packaging materials and so on.

According to the rough statistics of the construction material loss of buildings such as brick-concrete structures, all-cast-in-place structures and frame structures, in the construction process of every 10,000 square meters of buildings, only construction waste will produce 500 to 600 tons; For every 10,000 square meters of demolished old buildings, 7,000 to 12,000 tons of construction waste will be generated. After the mobile crushing station pulverizes the construction waste, most of them can be reused as renewable resources. Such as scrap steel, scrap wire, scrap wire and various scrap steel accessories and other metals, after sorting, concentration, refurnace, can be reprocessed into various specifications of steel; Brick, stone, concrete and other waste after crushing, can replace sand, used for masonry mortar, plastering mortar, concrete cushion, etc., can also be used to make blocks, paving bricks, lattice bricks and other building materials. Thus to realize the transformation from the traditional building materials - building - construction waste to the building materials - construction waste - recycling of raw materials.

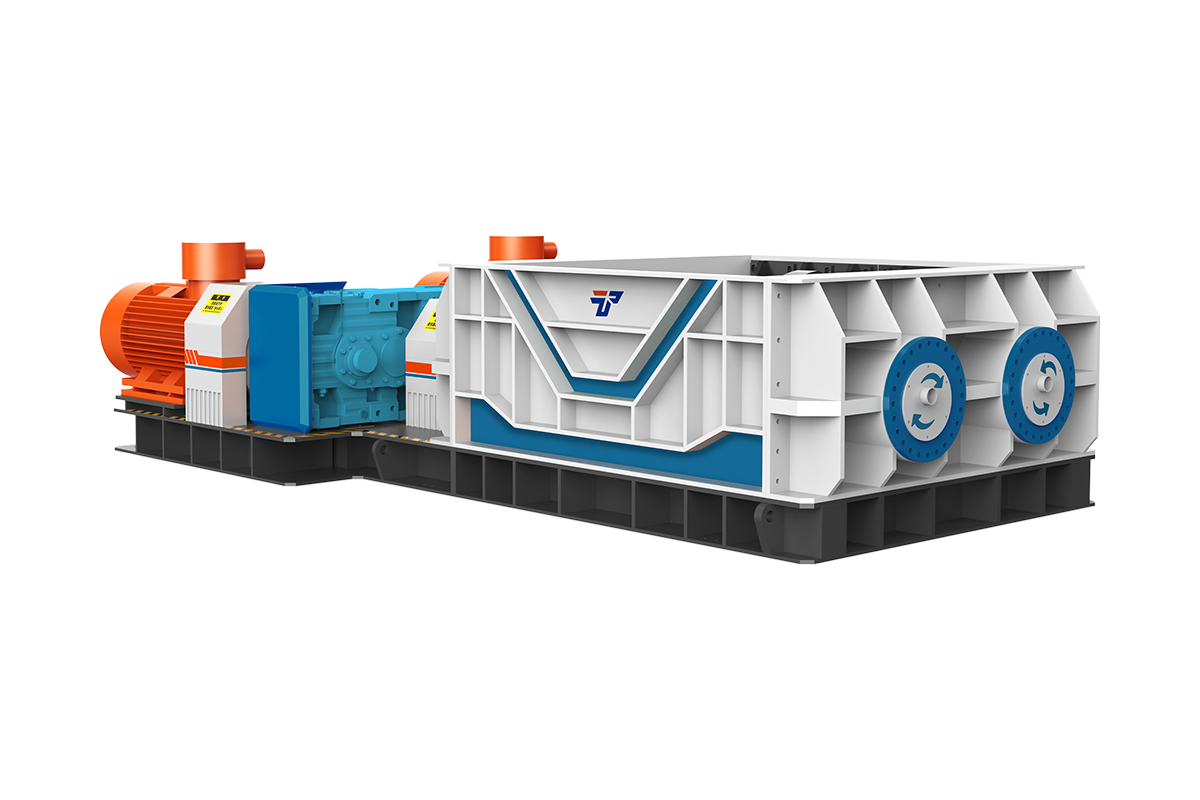

The mobile crushing station developed by our company for the treatment of solid construction waste is mainly composed of vibration feeder, jaw crusher (coarse crushing), magnetic separator, double-tooth crusher (impact crusher), vibration circle vibration), belt conveyor and so on. According to different process requirements, the combined structure of complete sets of equipment is optimized to give full play to its excellent performance.

After the solid construction waste is processed by the mobile screening crushing station, it is sorted into coarse, medium and fine aggregates, metals, wood, plastics and so on.

The coarse aggregate, fine aggregate and powder are transported to the concrete products production workshop, enter the mixing station, mix out the required concrete, use the brick press, wall panel production line to produce the concrete products required by customers, send to the curing bin for maintenance to the finished product, put into the finished product yard, and realize the recycling of construction waste resources.

OIL SHALE

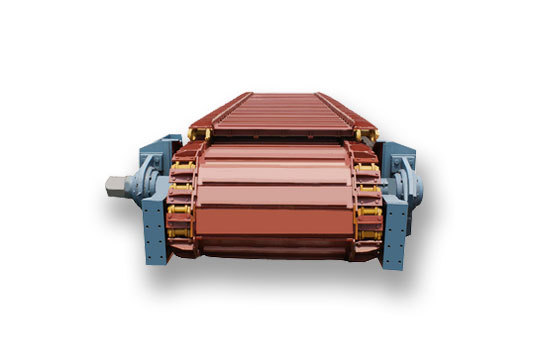

The strong double-toothed crusher produced by our company has been affirmed and praised by users for its stability, reliability and wear resistance of crushing teeth.

COKE

Used in coal chemical industry crushing coke double-tooth crusher, targeted tooth design, improve biting capacity, high block rate, low over crushing rate, large processing capacity. Increase the tooth height and tooth thickness to a large extent under the condition of ensuring the discharge particle size; Targeted research and development of special proportion of high wear-resistant materials, to overcome the coke "iron" ability, to a greater extent to improve the service life of wearing parts, to meet the user's use requirements.

PETROLEUM COKE, CLAY

Used in the petroleum coke crushing industry, supporting the silver structure with thin teeth, the wet material can be broken normally, avoiding the problem of sticking and blocking material, and the blocking rate is high, the discharge particle size is uniform and controllable, and the crushing efficiency is high.

Product inquiry

Note: Please leave your E-mail and our professionals will contact you as soon as possible!