Limestone double-toothed roller crusher

Classification:

Non -Coal Crushing Technology And Equipment

- Detail

-

- Commodity name: Limestone double-toothed roller crusher

The double-tooth crusher uses the theory of shearing, extrusion, and stretching to break materials. Its advantages are high block rate, low over-crushing rate, and regular product size.

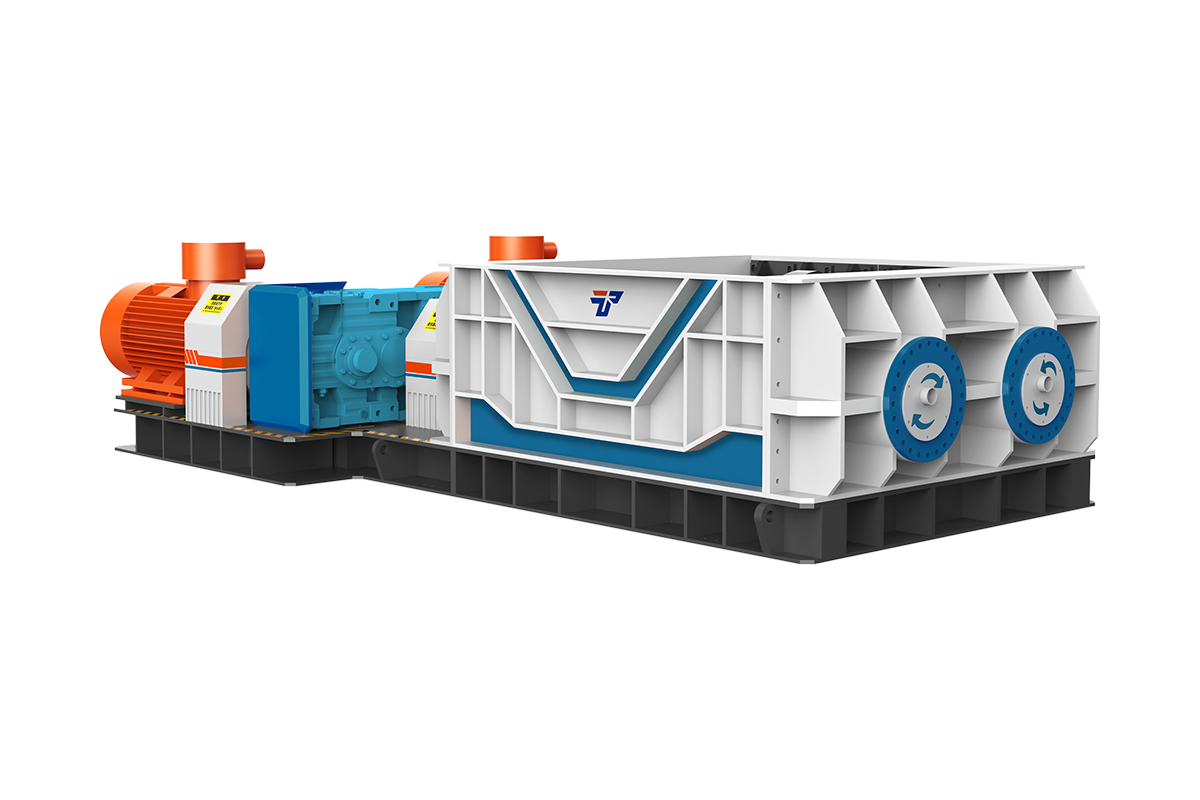

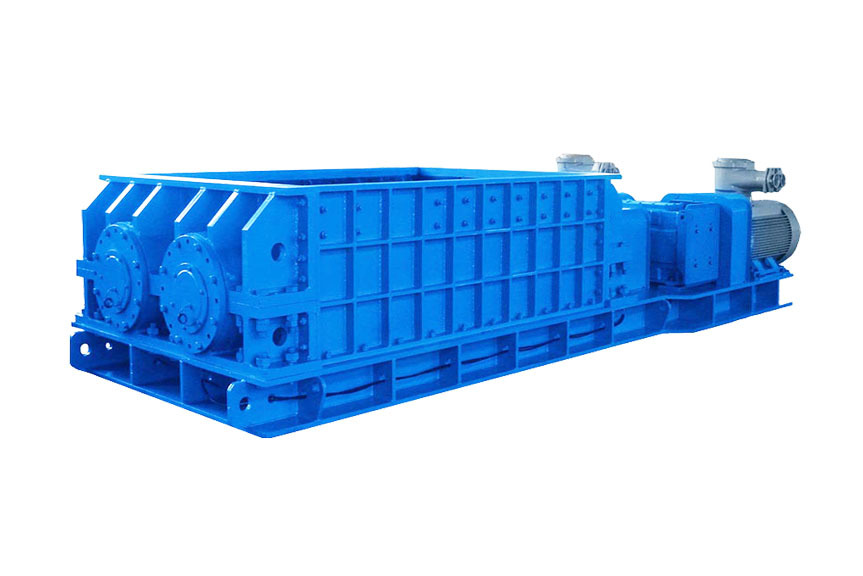

High-strength double-toothed roller classification crusher for limestone (direct-connected type) High-strength double-toothed roller classification crusher for limestone (rigid-flexible coupling type)

Introduction to the Limestone Double-Toothed Roller Crusher:

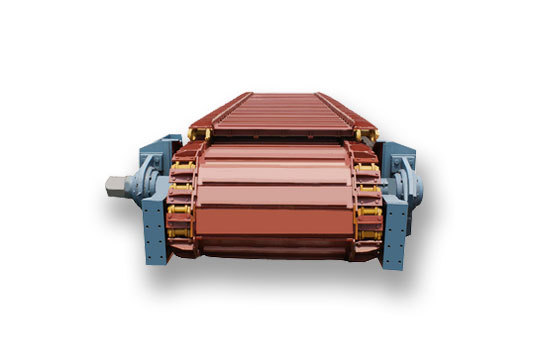

The double-tooth crusher uses the crushing theory of shearing, extrusion, and stretching on materials. Its advantages are high lump rate, low over-crushing rate, and regular output material shape.

Crushed limestone is mainly used in the production of calcium carbide or quicklime. Due to quality and process requirements, there are rigid requirements for the lump rate and material shape of the raw materials. The higher the lump rate and the more regular the particle shape, the better the quality of the finished product and the higher the production efficiency.

Advantages of Limestone Double-Toothed Roller Crusher:

Proven by use, compared with secondary crushing equipment in traditional crushing processes, such as hammer crushers, impact crushers, jaw crushers, and cone crushers, it has the following advantages:

Project

Traditional secondary crushing equipment

Advanced secondary crushing equipment

Equipment

Hammer crusher, cone crusher

Jaw crusher, cone crusher

Double-toothed roller crusher

Crushing principle

Impact

Extrusion

Shearing, stretching

Lump rate

30-40%

40%-55%

Increased by 15% or more

Material shape

Good material shape, close to regular polyhedrons or circles

Poor material shape, containing a large number of long strips and sheet materials

Uniform output particle size, the product is close to a regular polyhedron

Crushing efficiency

Low efficiency, needs to rely on quantity to compensate for the lack of output

High efficiency, single unit capacity can reach 1000t/h

Particle size adjustment

Adjustable, but difficult to operate

Adjustable, reliable positioning, convenient adjustment

Maintenance cost

Large amount of maintenance, high maintenance cost

Very little maintenance, low maintenance cost, long service life of crushing teeth

Resource utilization rate

Low utilization rate, serious over-crushing, resulting in a large waste of resources

Significantly improved

Economic benefits

In the industry of producing calcium carbide and quicklime from limestone, the particle size and material shape of limestone are strictly required.

Traditional secondary crushing equipment has a high over-crushing rate and poor material shape, which seriously affects the production efficiency and sales of limestone,

Producing excessive over-crushed materials, resulting in serious waste of resources.The finished product yield is increased by more than 15%, greatly improving the utilization rate of raw materials;

Good material shape, improving the quality of downstream products;

Low power consumption, saving electricity costs;

Small amount of maintenance, low maintenance cost, reducing operating costs.

Limestone crusher application site

Product inquiry

Note: Please leave your E-mail and our professionals will contact you as soon as possible!