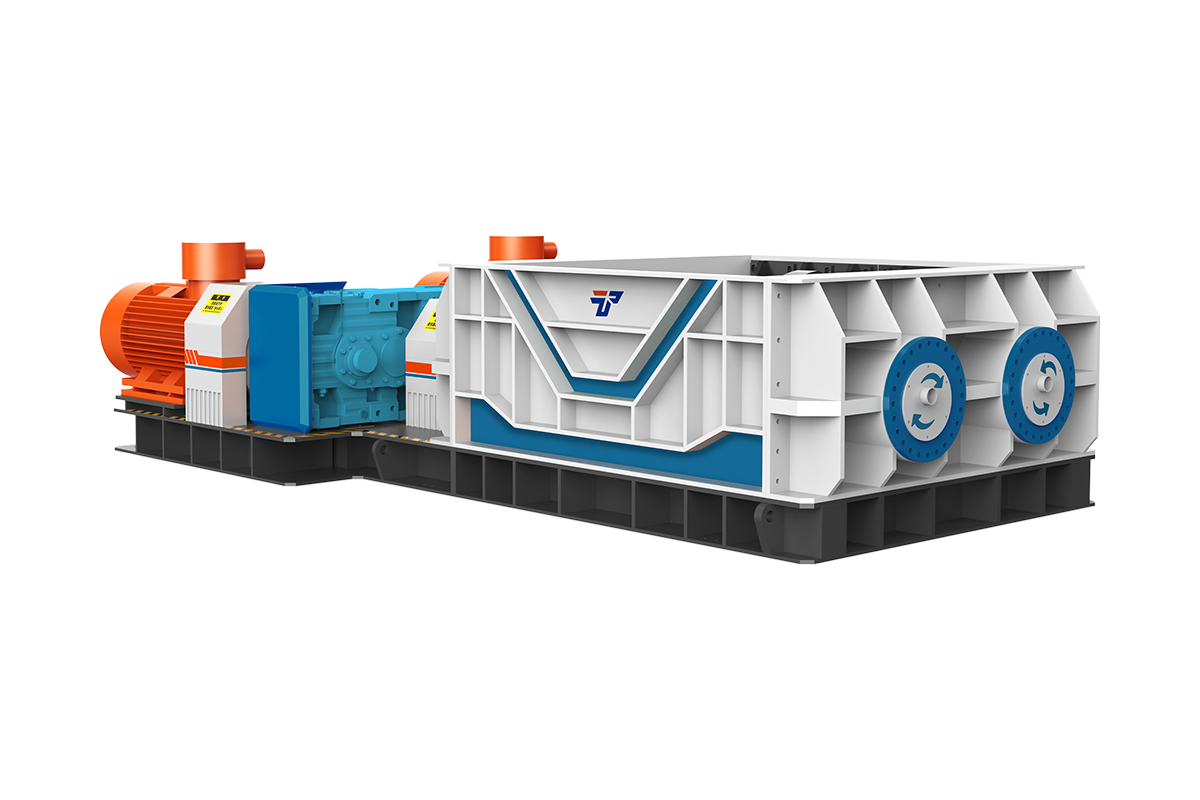

MGT SERIES HIGH EFFICIENCY ENERGY SAVING DRUM DRYING SYSTEM/DRUM DRYER SYSTEM/SLIME DRYING SYSTEM

Key words:

Classification:

Dry Environmental Protection Technology And Equipment

- Detail

-

- Commodity name: MGT SERIES HIGH EFFICIENCY ENERGY SAVING DRUM DRYING SYSTEM/DRUM DRYER SYSTEM/SLIME DRYING SYSTEM

DRYINGSYSTEM TECHNICAL FEATURE: ● Dehydration effect is obvious, the upper limit of feed moisture can reach 60%, the product moisture can reach below 8% ● Significantly improve the quality of materials and effectively improve the performance of material storage and transportation; ● The system is complete, efficient, energy-saving,eco-friendly, and has a high degree of automation; ● The equipment is safe and reliable, and the system operation and maintenance are convenient and simple.

DRYINGSYSTEM TECHNICAL FEATURE:

● Dehydration effect is obvious, the upper limit of feed moisture can reach 60%, the product moisture can reach below 8%

● Significantly improve the quality of materials and effectively improve the performance of material storage and transportation;

● The system is complete, efficient, energy-saving,eco-friendly, and has a high degree of automation;

● The equipment is safe and reliable, and the system operation and maintenance are convenient and simple.DRYINGSYSTEM APPLICATION:

● Deep dehydration and upgrading of raw coal, cleaned coal, slime, lignite, low-rank coal and other materials in the coal industry;

● Deep dehydration and upgrading of materials such as boiler fuel coal in the power industry;

● Mineral processing industry (such as nickel ore) ore concentrate, tailing and other materials drying;

● Drying of blast furnace slag, clay, sand,graphite and other materials in the construction industry.DRYINGSYSTEM SPECIFICATION:

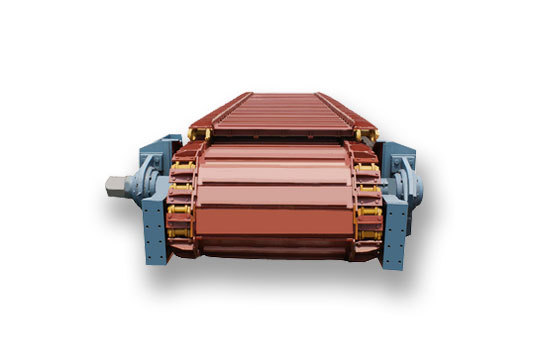

● Drying drum cylinder diameter from 1.5m to 4.2m, length from 8m to 38m, a total of 12 series of more than 60 specifications.

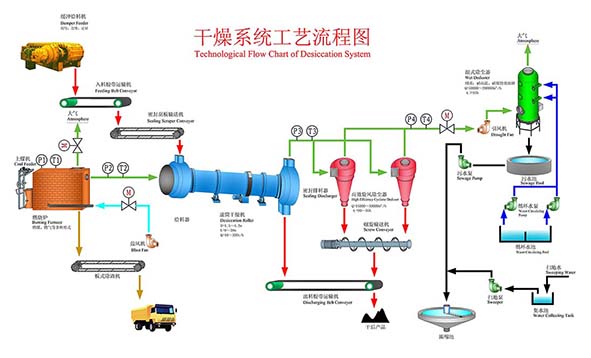

● The single dryer production capacity of coal slime can reach 180t/h, and other materials can reach 300t/h, fully meeting the needs of different users.PROCESS FLOW CHART

PROJECTS PROFILE:

Project : Lignite drying project

Dry material: lignite

Material feeding moisture: ≤33%

Discharging moisture of material: ≤15%

Capacity: 120 t/hProject: Coal slime drying system

Environmental indicators:

Particle concentration: 30mg/Nm3

Sulfur dioxide concentration: 200mg/Nm3

Nitrogen oxide concentration: 200mg/Nm3

Project: Coal Preparation Plant slime drying project

Dry material: tail slime

Water content of material: 28% ~ 31%

Material discharging moisture: 15% ~ 20%

Capacity: 120 t/h

Particle concentration: ≤30mg/m³

Sulfur dioxide concentration: ≤200mg/ m³

Nitrogen oxide concentration: ≤300mg/ m³Project: Slime drying system project

Dry material: tail slime

Material moisture: 24% ~ 16%

Material discharging moisture: 15% ~ 17%

Capacity: 140 t/h

Project: Slime drying system

Dry material: tail slime

Material moisture: ≤30%

Discharging moisture of material: ≤13%

Capacity: 30 t/hProject: Slime drying system project

Dry material: tail slime

Material moisture: ≤30%

Discharging moisture of material: ≤12%

Capacity: 90T /h

Project : Lignite drying project

Dry material: lignite

Material feeding moisture: ≤33%

Discharging moisture of material: ≤15%

Capacity: 120 t/h

Project: Coal slime drying system

Environmental indicators:

Particle concentration: 30mg/Nm3

Sulfur dioxide concentration: 200mg/Nm3

Nitrogen oxide concentration: 200mg/Nm3

Project: Coal Preparation Plant slime drying project

Dry material: tail slime

Water content of material: 28% ~ 31%

Material discharging moisture: 15% ~ 20%

Capacity: 120 t/h

Particle concentration: ≤30mg/m³

Sulfur dioxide concentration: ≤200mg/ m³

Nitrogen oxide concentration: ≤300mg/ m³

Project: Slime drying system project

Dry material: tail slime

Material moisture: 24% ~ 16%

Material discharging moisture: 15% ~ 17%

Capacity: 140 t/h

Project: Slime drying system

Dry material: tail slime

Material moisture: ≤30%

Discharging moisture of material: ≤13%

Capacity: 30 t/h

Project: Slime drying system project

Dry material: tail slime

Material moisture: ≤30%

Discharging moisture of material: ≤12%

Capacity: 90T /h

Product inquiry

Note: Please leave your E-mail and our professionals will contact you as soon as possible!