MNP series slime crusher

Key words:

Classification:

Coal Crushing Technology And Equipment

- Detail

-

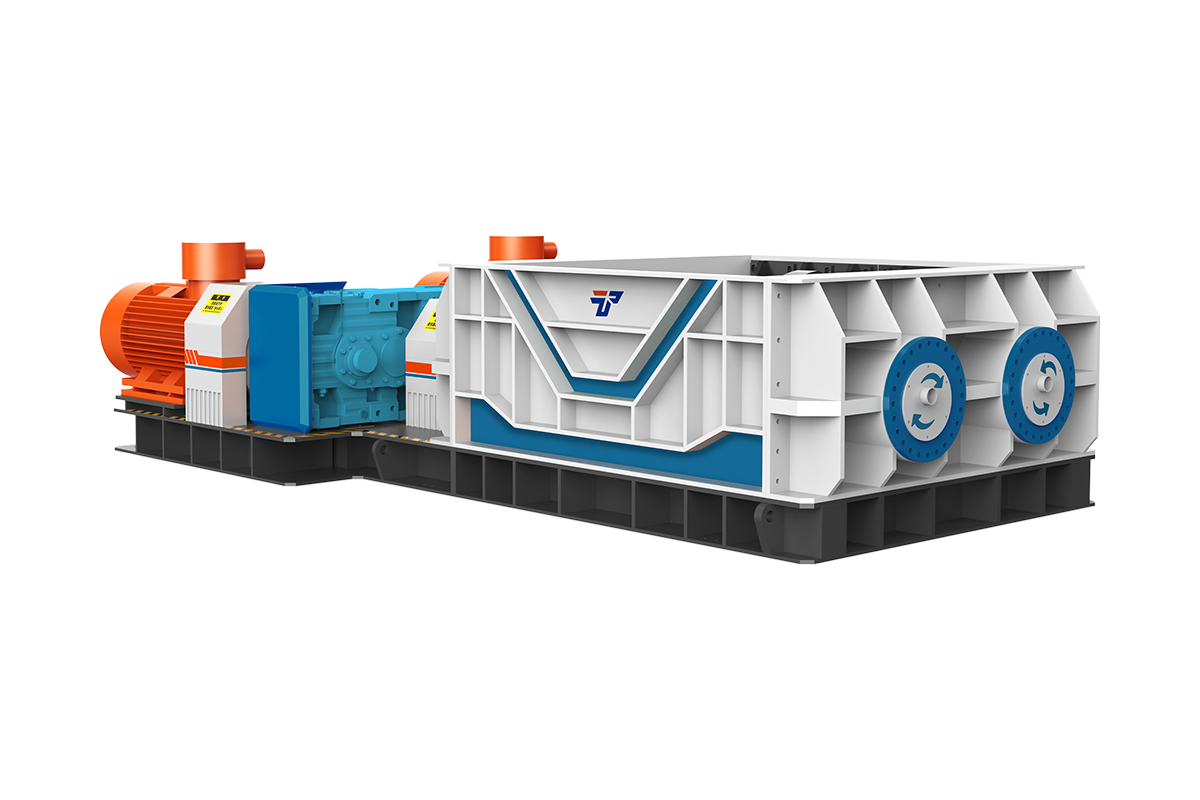

- Commodity name: MNP series slime crusher

MNP series slime crusher is a crushing equipment developed by our company on the basis of grading crusher according to the needs of the market. It is mainly used for crushing larger pieces of slime filter cake and bonding large pieces of slime. The slime crushed by the slime crusher developed by our company can be mixed into the power coal for sale, which not only meets the requirements of the current environmental protection slime can not fall to the ground, but also greatly improves the production efficiency of the enterprise.

MNP series slime crusher is a crushing equipment developed by our company on the basis of grading crusher according to the needs of the market. It is mainly used for crushing larger pieces of slime filter cake and bonding large pieces of slime. The slime crushed by the slime crusher developed by our company can be mixed into the power coal for sale, which not only meets the requirements of the current environmental protection slime can not fall to the ground, but also greatly improves the production efficiency of the enterprise.

Technical features

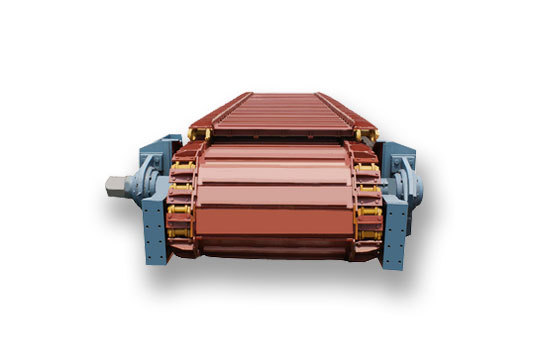

1. The spiral blade movable tooth scraper structure is adopted, which can be replaced separately. The crushing principle of shearing and splitting is adopted to reduce the contact area between the crushing tooth pair and the material. The blade is spirally arranged, and during the biting process of the crushing roller, the material is forced to enter the crushing cavity evenly, thus preventing the material from accumulating fixed points for a long time and effectively biting into large pieces of material;

2. The crushing scrapers that are staggered and undercut with each other are arranged on the two relatively rotating crushing rollers, which can realize self-cleaning, do not bond the crushing scrapers and double rollers, and overcome the shortcomings of equipment failure due to slime bonding;

3. The unique string breaking device effectively guarantees the product's discharge granularity;

4. It has three functions of mixing, stirring and crushing, and can mix and crush coal slime and raw coal, and mix evenly;

5. The split box structure and advanced sealing system effectively separate the bearing position from the crushing chamber, realize zero damage to the bearing seal in the process of material crushing, and ensure that the crusher runs in harsh environments without leaking dust, water and slime.

6. The maximum feed particle size is 500mm and the maximum production capacity is 800 t/h.

Product inquiry

Note: Please leave your E-mail and our professionals will contact you as soon as possible!