Mobile crushing station (including semi-mobile crushing station and fixed crushing station)

Key words:

Classification:

Coal Crushing Technology And Equipment

- Detail

-

- Commodity name: Mobile crushing station (including semi-mobile crushing station and fixed crushing station)

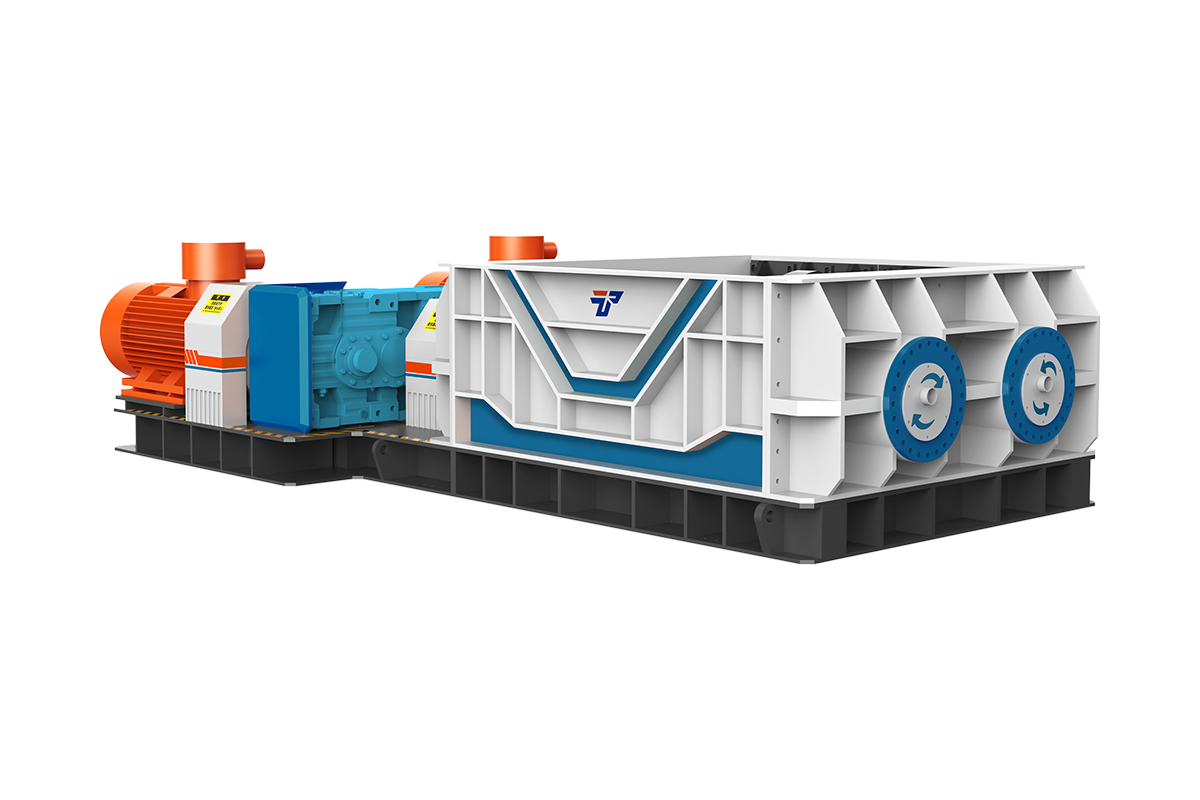

The mobile crushing station integrates feeding, crushing, conveying and screening, and can adjust its position at any time with the movement of the working surface.

Application of crushing station:

● Solve the needs of large and medium-sized open-pit coal mine materials receiving, feeding, crushing, screening, transportation, temporary storage and other operations;

● Generally used in coal, mineral processing, construction and other industries to crush raw coal, coal washing, coal slime, lignite, coal gangue, iron ore, gypsum mine, kaolin, limestone and other materials.

It is widely used:

Coal mines such as underground coal mines, coal washing plants, open-pit coal mines, etc. Raw coal, medium coal, clean coal, coking coal, fired coal, sintered coal, coal gangue, power coal, power coal, oil shale, lignite, slime filter cake, hard coal, petroleum coke, crude oil coke, slime, lump coal, mixed coal, wool coal, carburant, long flame coal, sinter, etc.

● Gold ore, white sandstone, lead-zinc ore, copper ore, dolomite, talc, phosphate, slag, basalt and other mines and quarries.

● Electrolyte anodes and other aluminum manufacturers.

● Chemical plants, such as calcium carbide.

● Power plants such as lignite.

● Wet sticky materials, such as bauxite, laterite nickel ore, nickel ore, clay, etc.

● Limestone quarries, such as limestone 40-80mm, 50-90mm, 20-40mm, gypsum, calcium carbonate, bluestone, etc.

Technical characteristics of crushing station:

● A large-scale crushing and screening production complete system integrating the processes of receiving, feeding, crushing, conveying, screening and temporary storage;

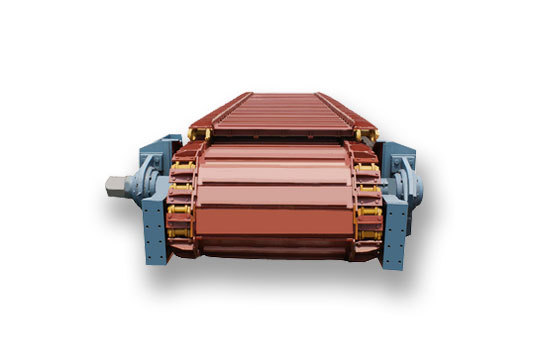

● Double-toothed roller crusher, large vibrating screen, box-type substation, complete electrical system, monitoring system and other major equipment and supporting steel structure platform;

●It has the advantages of low investment cost, compact structure, stable operation, short production, installation and commissioning cycle, strong mobility, and intelligence;

●Strong adaptability, suitable for coarse crushing and medium crushing and screening system. It can work independently with stand-alone equipment and form a flexible system for joint operation;

● Complete electrical and monitoring system can realize remote centralized control and monitoring, the whole system adopts PLC control, high degree of intelligence;

● Advanced design, excellent performance, stable and reliable operation, short construction period, high production efficiency, convenient use and maintenance, and low operating cost.

The mobile crushing station integrates feeding, crushing, conveying and screening, and can adjust its position at any time with the movement of the working surface.

The driving mode of the mobile crushing station is traction mobile or crawler self-moving, compact structure, suitable for open-pit mine production, and the maximum production capacity is 500 t/h.

The crushing equipment is equipped with double-toothed roller crusher, jaw crusher and bipolar hammer crusher. The wear-resistant parts are made of babbitt wear-resistant alloy developed by our company, with hardness HRC45 ~ 55 and impact toughness ak≥ 38kg * m/cm.2, Strong impact resistance and long service life.

Crawler mobile crushing station Tire type mobile crushing station

Technical characteristics of mobile crushing station:

1. Belt conveyor:

There are two types of fixed and mobile, with simple structure and high efficiency. A continuous conveying machine with a flexible conveyor belt as a material bearing and traction member. An endless belt is looped around the drive pulley and the redirection pulley. The upper and lower branches between the two rollers are each supported by several idlers. The material is placed on the upper branch, and the friction between the driving roller and the belt is used to drag the conveyor belt and the material to run. It is suitable for conveying bulk materials and finished products in horizontal and inclined directions, and can also be used in assembly lines for certain process operations. Simple structure, stable and reliable work, strong adaptability to materials, large conveying capacity, low power consumption, and wide range of uses.

2. Hydraulic lifting legs:

The lifting of the hydraulic outrigger is controlled by a manual valve. During transportation, the hydraulic cylinder is raised, and the outriggers are mechanically fixed with pin shafts to facilitate transportation; when the vehicle moves in place and needs normal production, the hydraulic cylinder is lowered to make the vehicle more stable. Since most of the weight of the whole vehicle is concentrated in the middle, the four legs at the rear of the whole front of the vehicle are raised/lowered first during operation, and then the two legs in the middle are operated to prevent the legs from being damaged due to excessive pressure.

3. Hydraulic oil station:

The hydraulic oil station sends the pressure oil into the hydraulic cylinder, folds the feeding bin, breaks the upper cover of the feeding port, folds the unearthed belt, and lifts the outrigger hydraulic cylinder. It should be noted that when using the hydraulic station to lift the hydraulic outrigger, due to the high oil pressure of the entire hydraulic system, other on-board hydraulic components cannot be used to avoid damage to other hydraulic components.

The hydraulic oil tank is provided with a sight glass, an oil level sensor and a temperature sensor. When the oil level is lower than the set limit value, the oil level sensor automatically closes the vibrating feed groove.

The same happens with the temperature sensor when the oil temperature is too high. There is a delay of about 30 seconds to shut down the hydraulic system. The tank has a capacity of 480 litres. When filling the hydraulic oil tank, keep a distance of 10cm between the oil level and the upper edge of the oil tank. The drain valve is located at the bottom of the tank. On the other hand, the pressure oil can be fed into the hydraulic cylinder, the feed bin can be folded up, and the upper cover of the feed port and the excavation belt can be folded up. In order to prevent the hydraulic oil from overheating, there is a special fan for cooling.

4. Working platform:

The working platform is connected to the feeding port of the feeder and the placement platform of the diesel generator set, so that the operator can easily and safely reach all corners of the vehicle and monitor the remote rotation of the equipment; but it can also be used for equipment maintenance when equipment problems occur. And maintenance, system calibration inspection, the working platform is fixed on the system, and there is no need to disassemble during transportation.

5. Control system:

All equipment operations can be completed through the touch screen, providing a one-key start-stop function, the vehicle automatically starts and stops the equipment in turn, and normal production operations can be performed without work experience. The touch screen is menu-based and can be used quickly. You can understand the working information of the required equipment through the touch screen: the speed of the crusher, the frequency of the feeder, the temperature of the oil, etc. At the same time, the operation of the equipment is monitored, and the vehicle can be controlled through the touch screen when needed. The outside of the touch screen is protected by a dustproof electric control cabinet, which can ensure that the touch screen can work stably for a long time under harsh working conditions. The touch screen is attached to the lower side panel of the corridor for safe and non-hazardous operation.

YDP90150 wheeled mobile crushing plant 200-300 tons/hour

Tire type mobile crushing station YDP90150 type

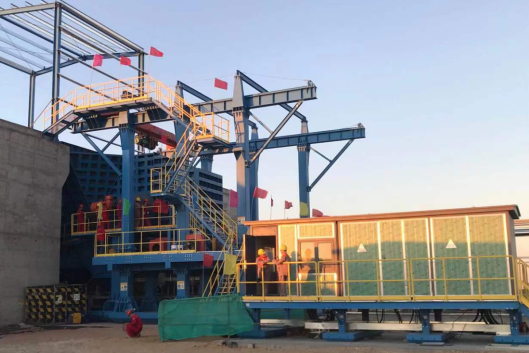

Case:

5 million tons/year

1400 t/h open-pit coal mine raw coal crushing and screening station

semi-mobile crushing station

150 t/h mobile crushing station/gangue crushing station

1500 t/h oil shale crushing station

Modular combination of semi-mobile crushing and screening station

Product inquiry

Note: Please leave your E-mail and our professionals will contact you as soon as possible!